Wearable Multi-Measuring System.

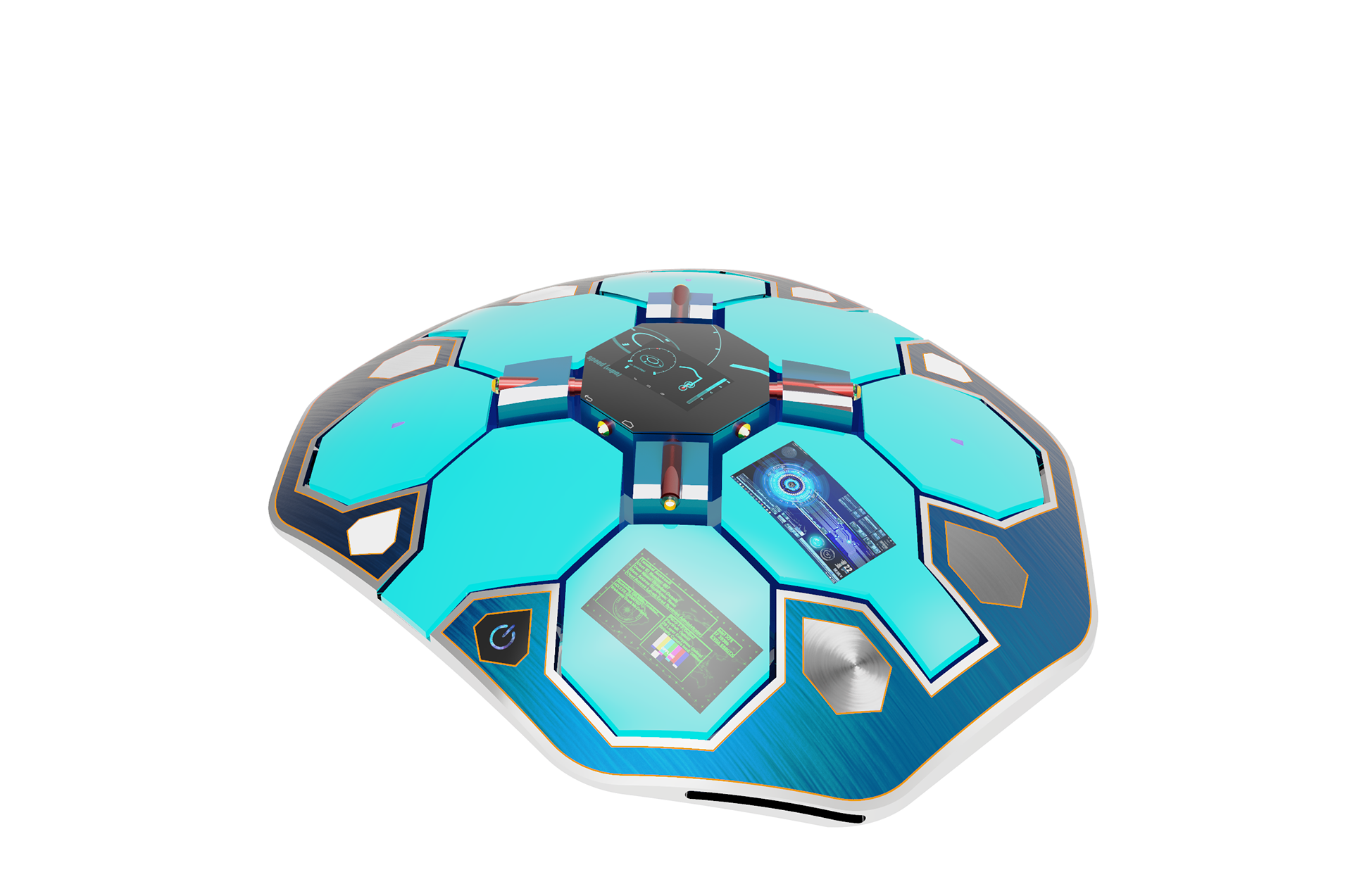

Camera, Thermal Cameras, Digital Measuring Tool, and Laser Distance Sensor

Introduction

The Zinc Challenge is a competition created by the International Zinc Association for engineering and design students who are currently enrolled at a college or university. Students are encouraged to user their imagination to create, design, and develop a wearable Electronic Device made by zinc die casting.

It will be an electronic measuring device to assist in calibrating, measuring, and recording data on site, in the field, and hard to reach places.

Why Zinc?

Specific alloys allow for precise thin walls that can help in the design of strong detailed structures. Dimensional stability and high accuracy are critical for precision readings. Complex intricate shapes are possible for multiple parts and assemblies. Corrosion resistance offers additional protection in harsh environments.

Electrical conductivity is great for grounding and shock protection.

Heat sink properties help dissipate high temperature generated during operation.

Great bearing properties for moving parts.

Excellent RFI/EMI Shielding capabilities.

Wide range of finishing options.

Research

From James Bond’s gadgets decades ago to the Apple Watch, wearables have become increasingly popular over the past few years. The idea of been able to connect with everything, interact with everyone and increase basic human capabilities.

Exponetially this can become very useful in many industries and can help workers perform better at the same time that they can increase safety.

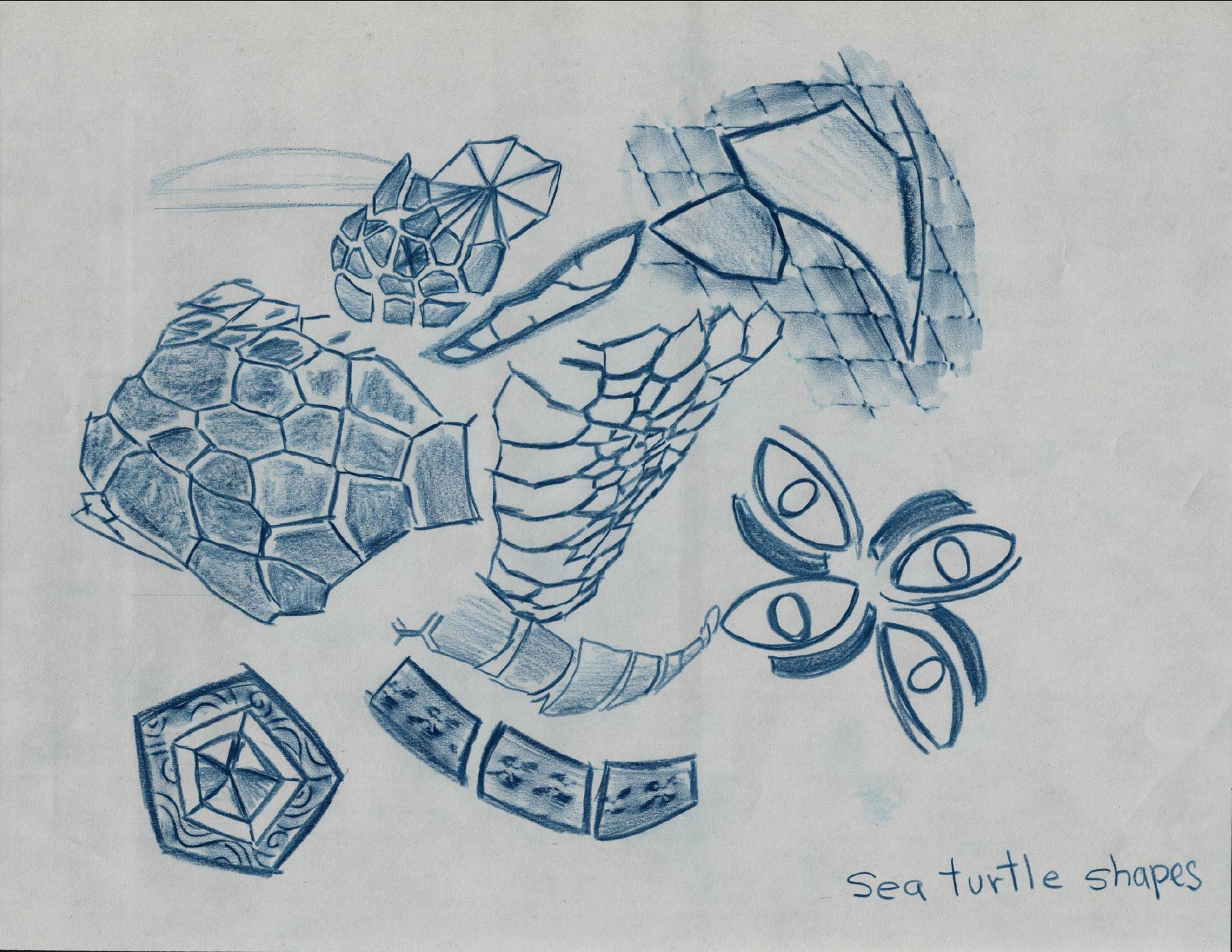

Inspiration

Target Market

Surveyors

Architects

Engineers

Field Inspectors

Non contact test personnel

Design Development

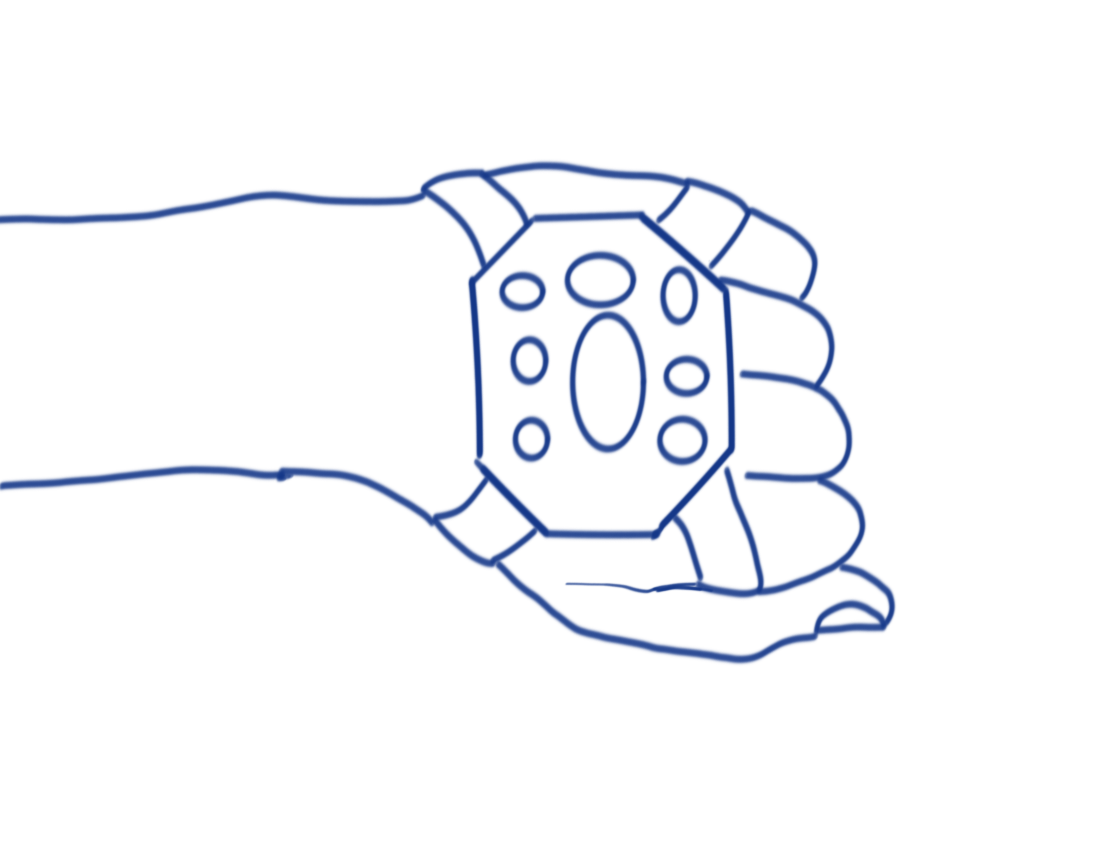

Sketches

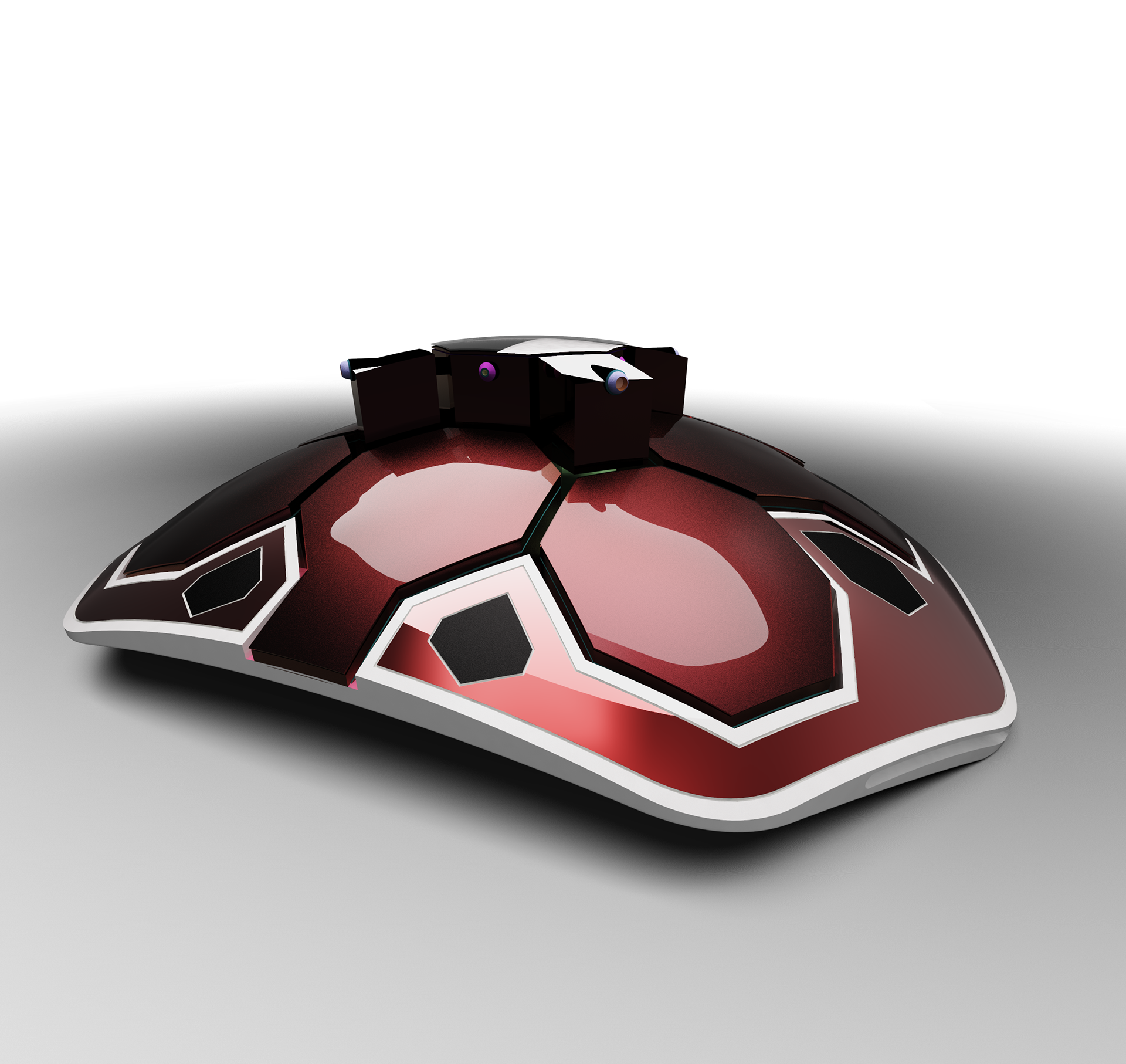

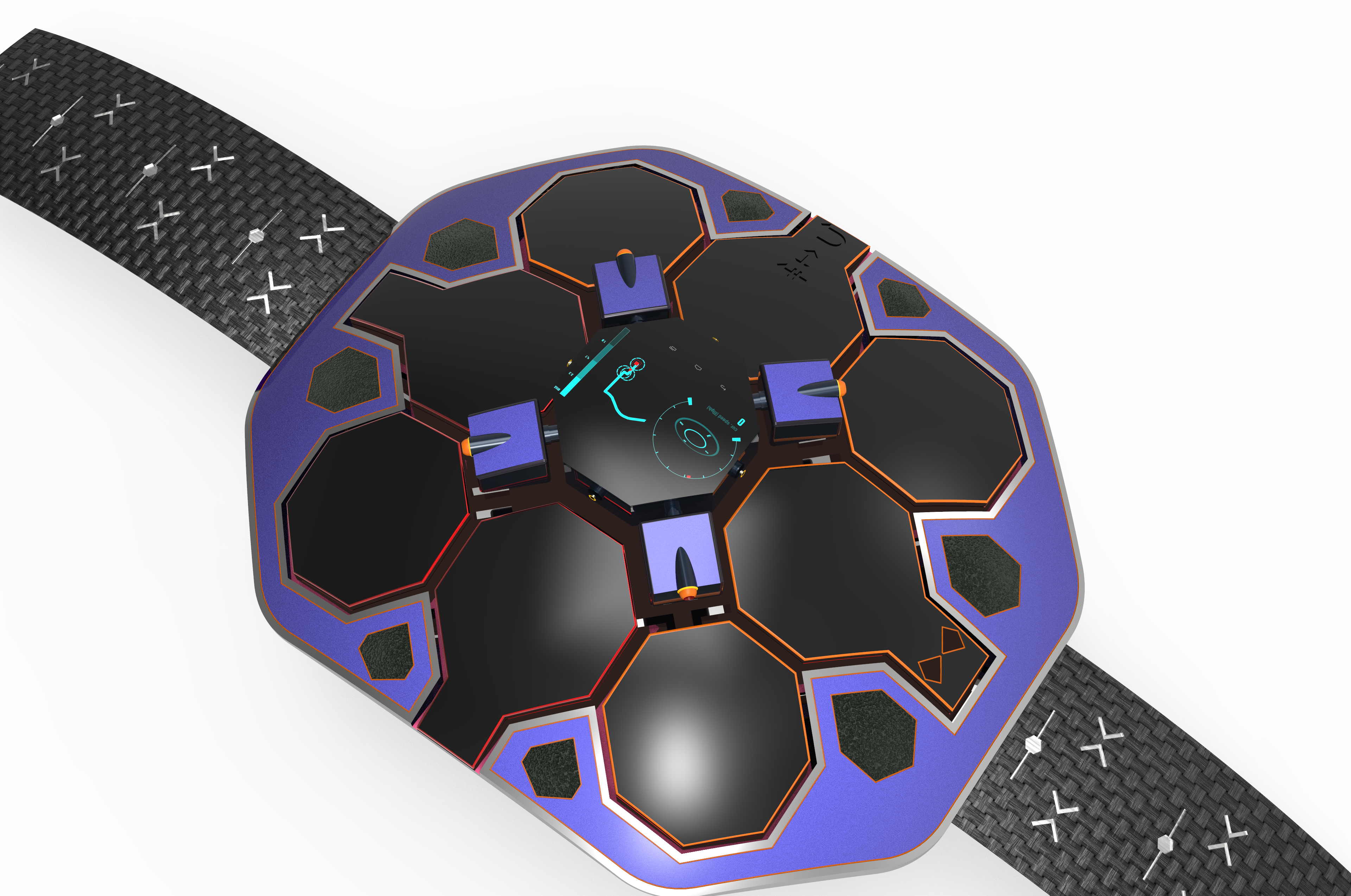

Modeling, Function, and Details

Color Material Finishes

Applications

- Inspection

- Surveying

- Construction

- Architecture

- Manufacturing

- Design, engineering, production.

- Fixtures and jigs

- Sheet metal - Body in White

Advantages

- Flexibility and mobility enables fast on-site inspection and interventions

- Reduces production stops and scrap

- Multi-sensor ready: Tactile probing and non-contact laser scanning

- High accuracy measurements

- Full measurement freedom due to walk-around Multi-Sided Probe

- Dynamic referencing enabling measuring of unstable parts

- Easy one man set-up and use